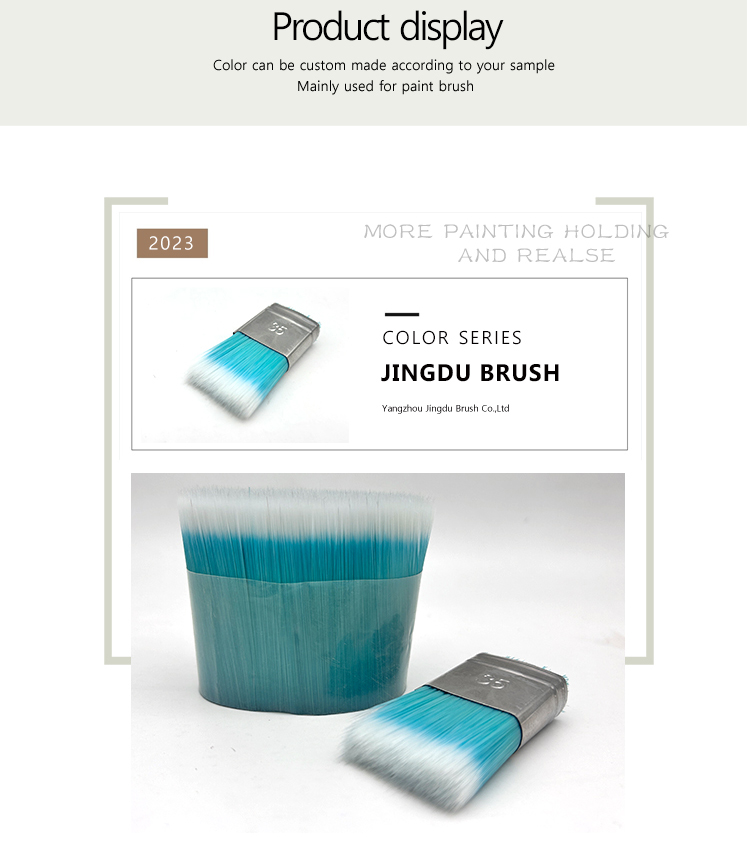

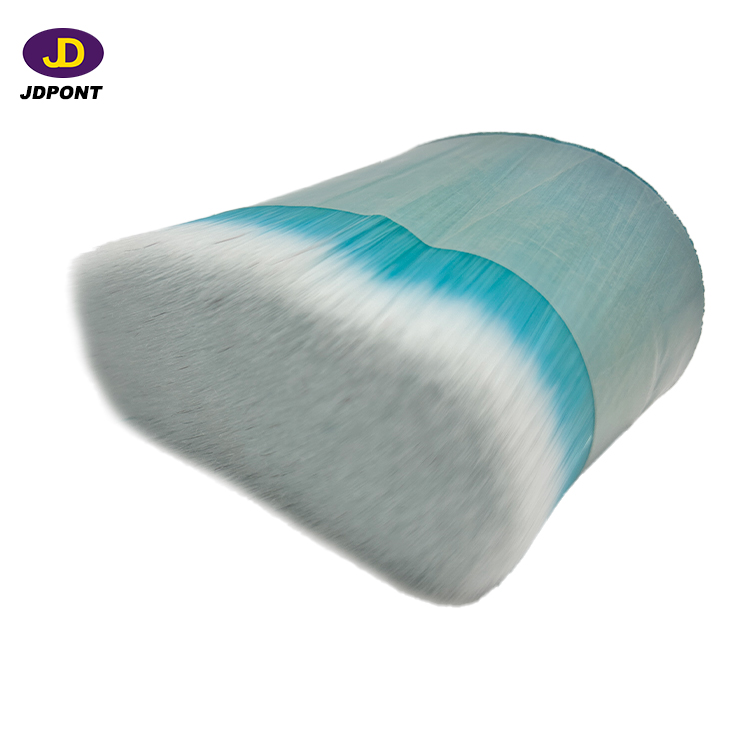

Physical TAPERED GREEN BRUSH FILAMENT

Model : JDPTF-G

Features : green

Material : synthetic filament

Description : A physical tapered green brush filament is a specialized type of brush bristle designed with a distinct green coloration and a unique tapered shape. This type of filament is commonly used in various applications, including painting, cleaning, and industrial processes, where its specific features offer several advantages.

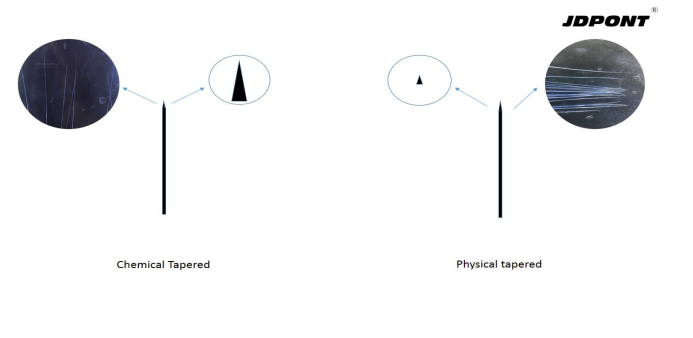

What is the difference between physical tapered and

chemical tapered?

Chemical tapered: it is through the caustic soda to make the tip sharp.

Physical tapered: it is through machine to make the tip sharp

Why customers choose physical tapered?

1. Physical tapered is environmental products, no need withing caustic soda this kind of chemical, and no need washing them.

2. Physical tapered is mainly used of solid filament, nylon filament, which is stiff. Have a long term uselife

3. Nylon can not be chemical tapered

Why customers choose chemical tapered?

1. It is more cheaper compared with physical tapered

2. The tip of chemical tapered is more softer than physical tapered

| Brand | JDPONT |

| Length | 57-114mm |

| Length Control | ±1mm |

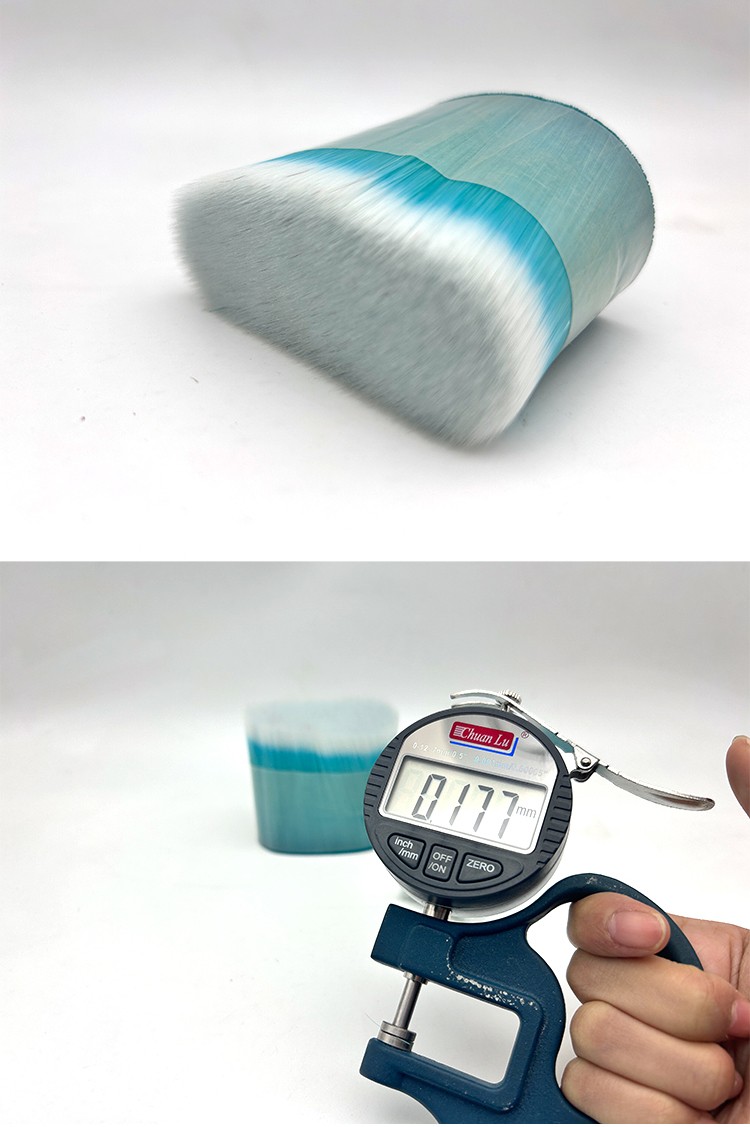

| Diameter | 0.16-0.18mm |

| MOQ | 200kg/Length |

| Material | 25% PBT/75%PET |

| Material Source | Sinopec |

| Color | Red/White Tip Blue/White Tip Yellow/white Tip Purple/White Tip Customized |

| Crimped | No |

| Feature | Solid |

| Flagged | Mild |

| Clean | No fade |

| Slippery | Middle |

| Suitable for Machine | Yes |

| Use | Paint Brush/Shoe Brush/ Broom Brush/Hair Brush/Artist Brush |

| Glue | Epoxy Resin Polyamide Resin |

| Painting | water based |

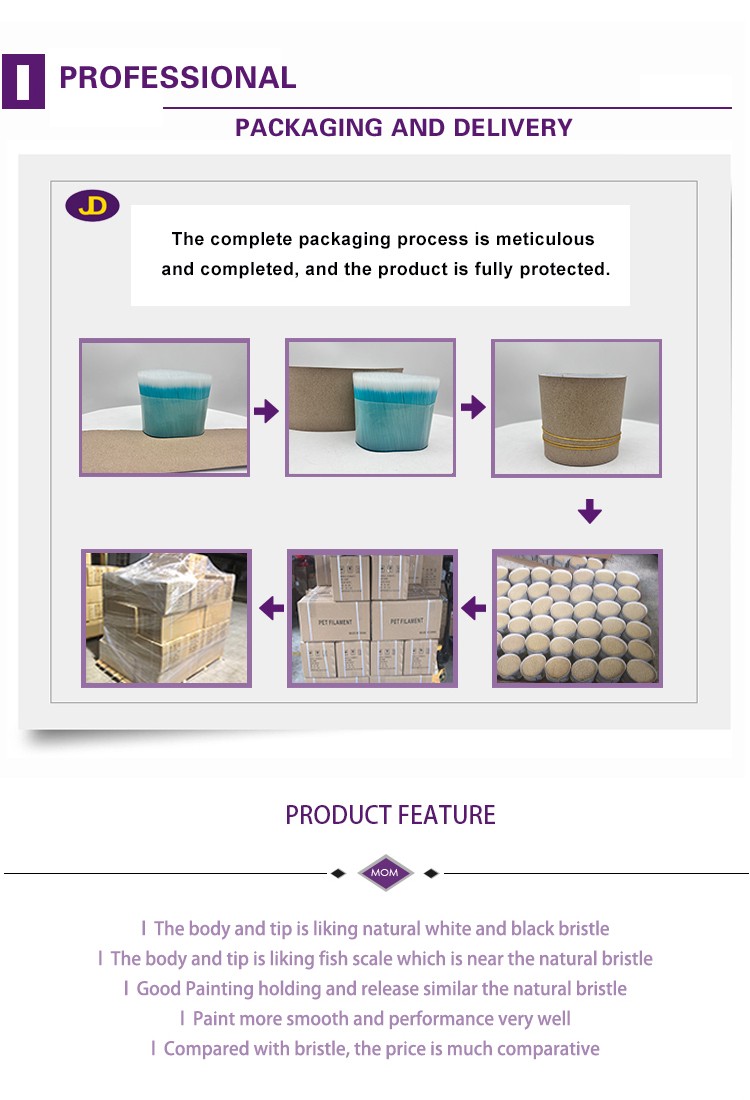

| Packing Size | 65*32*33cm/25KG |

| Carton | 5 Layers |

| 20 GP | 10 tons |

| 40 HQ | 23.5 tons |

| Elasticity | Highly |

| Flexibility | Highly |

A physical tapered green brush filament is a specialized type of brush bristle designed with a distinct green coloration

and a unique tapered shape. This type of filament is commonly used in various applications, including painting, cleaning,

and industrial processes, where its specific features offer several advantages.

**Key Features:**

1. **Green Color:** The filament is characterized by its vibrant green hue, which not only distinguishes it from other filaments

but also makes it easily identifiable for specific tasks or industries.

2. **Tapered Shape:** The filament has a gradual taper, meaning that it starts wider at the base where it is attached to the

brush handle and narrows down gradually towards the tip. This tapering provides various functional benefits:

- **Enhanced Paint Pickup:** In painting applications, the tapered shape allows for efficient pickup and distribution of paint,

resulting in smoother and more even brush strokes.

- **Improved Cleaning Performance:** For cleaning brushes, the tapered filament helps in removing dirt, debris, and stains

effectively due to its versatile shape, which can reach into corners and crevices.

- **Versatility:** The tapered filament can adapt to various surfaces and contours, making it suitable for a wide range of tasks,

from fine detailing to broader strokes.

- **Reduced Brush Marks:** When used in artistic endeavors, the tapered shape minimizes visible brush marks on the canvas,

contributing to a more polished and professional finish.

3. **Durable Material:** The green brush filament is typically constructed from durable and resilient materials, ensuring longevity

and resistance to wear and tear. This makes it suitable for repeated use in demanding applications.

4. **Compatibility:** These tapered green brush filaments are compatible with various brush types and can be found in paintbrushes,

cleaning brushes, and other specialty brushes designed for specific purposes.

5. **Ease of Identification:** The distinctive green color makes it easy to spot and recognize these filaments, helping users quickly

identify the brush they need for a particular task.

Overall, the physical tapered green brush filament combines its unique coloration with the advantages of a tapered shape to provide

efficient and versatile solutions for painting, cleaning, and various industrial applications. Whether you're an artist, a DIY enthusiast,

or a professional in need of precision and reliability, these filaments offer a valuable tool to help you achieve your desired results.

How we tapered our filament and control our tapering?

Yangzhou Jingdu Brush Co.,Ltd is a factory who are producing bristle and brush filament. At the moment, we have two ways to

tapered our filament, one is physical tapered , and one is chemical tapered filament.

Let’s introduce how we make chemical tapered filament:

1. Different sharp of filaments will use different degree of acid-base concentration. We will measure the degree of acid accordingly to kinds of filament

2. Put the filaments in the acid water in a certain position

3. After boiling, checking how much they have reflected and keep watching until they have finished, and washed them to measure the size to check if it is ok

4. Put the finished tapered filament in the accurate place.

The most important is that to pay more attention to degree of acid-base concentration, if too high, then the filament would be shorted.

Skilled and trained Workers are more necessary for making chemical tapered filament.

20017-2022 Yangzhou Jingdu Brush Co.,Ltd

20017-2022 Yangzhou Jingdu Brush Co.,Ltd

Subscribe

Subscribe